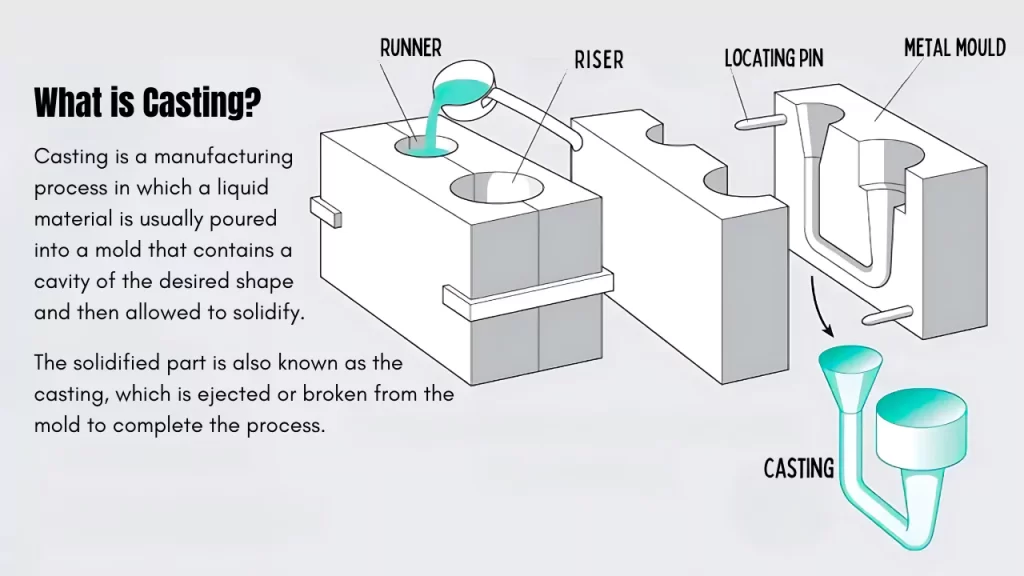

Metal casting is a manufacturing process in which manufacturers pour molten metal into a mold to create a desired shape. After the metal cools and solidifies, they remove the mold, leaving behind the final metal object.

Industries such as automotive, aerospace, and construction widely use this process to produce components with complex shapes that other methods would find difficult or expensive to manufacture.

Steps in Metal Casting:

Pattern Making – Creating a replica of the final product.

Mold Making – Forming a cavity in which molten metal will be poured.

Melting and Pouring – Heating the metal to a liquid state and pouring it into the mold.

Cooling and Solidification – Allowing the metal to cool and harden.

Removing the Casting – Taking the solidified metal out of the mold.

Finishing – Cleaning, machining, or polishing to achieve the final shape and surface quality.

Types of Metal Casting:

Sand Casting – Uses sand molds, ideal for large or complex shapes.

Investment Casting – Uses wax patterns, providing high accuracy and detail.

Die Casting – Uses metal molds, suitable for mass production with excellent surface finish.

Centrifugal Casting – Rotates the mold to distribute metal, often used for pipes and cylinders.

Advantages of Metal Casting:

Complex Shapes – Can create intricate designs that would be difficult with machining or welding.

Cost-Effective for Large Production – Ideal for mass production, reducing material waste.

Wide Range of Metals and Alloys – Can cast ferrous (iron-based) and non-ferrous metals (aluminum, copper, etc.).

Size Flexibility – Can produce small, precise components or large, heavy structures.

Recyclability – Many casting processes allow for metal recycling, reducing waste.

Disadvantages of Metal Casting:

Porosity and Defects – Air pockets or impurities can weaken the final product.

Limited Mechanical Properties – what is casting of metal? It may be more brittle than forged or machined metals..

High Initial Costs – Mold and pattern-making can be expensive.

Surface Finish Issues – Some methods require additional finishing to improve smoothness and precision.

Applications of Metal Casting:

Automobile Industry – Engine blocks, transmission housings, brake drums.

Aerospace Industry – Jet engine components, turbine blades.

Construction – Pipes, beams, valves, and heavy machinery parts.

Art and Sculptures – Bronze statues, decorative metalwork.

Electronics – Heat sinks, enclosures for electrical components.

Modern Advancements in what is casting of metal?:

3D Printing in Casting – Rapid prototyping using additive manufacturing to create detailed molds.

Automated Casting Processes – Robotics and AI-driven systems improve precision and efficiency.

Advanced Alloys – New materials that enhance strength, corrosion resistance, and durability.

Detailed what is casting of metal? Processes

Sand Casting

Sand casting, a widely used and ancient technique, utilizes a sand-based mold to create the intended shape.

Process:

Manufacturers create a pattern (a replica of the final part) from wood, plastic, or metal.

First, manufacturers place the pattern in a box and pack sand mixed with a binding agent around it to form the mold.

After removing the pattern, they create a cavity for the metal.

Next, they pour the liquefied metal into the mold and allow it to solidify as it cools.

Once solidified, they break the sand mold to extract the casting and then thoroughly clean and refine it to achieve the desired finish.

Advantages:

Low cost and suitable for small-batch production.

Can cast large and complex shapes.

Compatible with a wide range of metals.

Disadvantages:

Surface finish is rough.

The mold is destroyed after each use.

Possible defects such as sand inclusion and porosity.

Investment Casting (Lost Wax Casting)

This method is used for precision and high-quality castings, often for aerospace, jewelry, and medical applications.

Process:

Manufacturers make a wax pattern that matches the final product.

Manufacturers coat the wax pattern with a ceramic slurry and allow it to harden.

After melting out the wax, they create a hollow ceramic mold, which they fill by pouring in molten metal.

After the metal solidifies, they break the ceramic mold, revealing the metal casting.

They clean and finish the casting.

Advantages:

Produces fine details with excellent surface finish.

Can cast complex shapes with thin walls.

Minimal machining required.

Disadvantages:

High production cost and time-consuming.

Limited to smaller parts.

Die Casting

Die casting is a high-speed, high-precision method used for mass production of metal parts.

Process:

A reusable metal mold (die) is created.

Molten metal is injected under high pressure into the mold cavity.

The metal quickly cools and solidifies.

The mold opens, and the finished casting is ejected.

Advantages:

Excellent surface finish with high dimensional accuracy.

Suitable for large production runs.

Minimal finishing required.

Disadvantages:

High initial cost for dies.

It is restricted to non-ferrous metals such as aluminum, zinc, and magnesium.

Not ideal for very large or complex parts.

Centrifugal Casting

This method is mainly used for producing cylindrical components such as pipes and rings.

Process:

A rotating mold is used, and molten metal is poured inside.

The spinning motion drives the molten metal outward, pressing it firmly against the mold walls.

The metal solidifies, creating a hollow cylindrical casting.

The casting is removed and finished.

Advantages:

High strength and uniform grain structure.

Reduced impurities due to centrifugal force.

Ideal for producing seamless tubes and hollow parts.

Disadvantages:

Limited to symmetrical parts.

Requires specialized equipment.

Common Casting Defects and Their Causes

Porosity – Air bubbles trapped inside the casting due to improper degassing.

Shrinkage – Formation of cavities due to uneven cooling.

Cracks – Occur due to thermal stress and improper mold design.

Inclusions – Presence of unwanted particles due to poor mold material.

Misruns – When metal does not fill the mold completely, often due to low pouring temperature.

To prevent these defects, manufacturers use techniques such as vacuum casting, improved mold design, and optimized pouring temperatures.

Future of Metal Casting

With advancements in technology, metal casting is becoming more efficient and precise. Some key trends include:

3D Printing for Molds – Reducing lead times and enabling complex designs.

AI & Automation – Improving quality control and reducing defects.

Eco-friendly Casting – Using sustainable materials and reducing energy consumption.