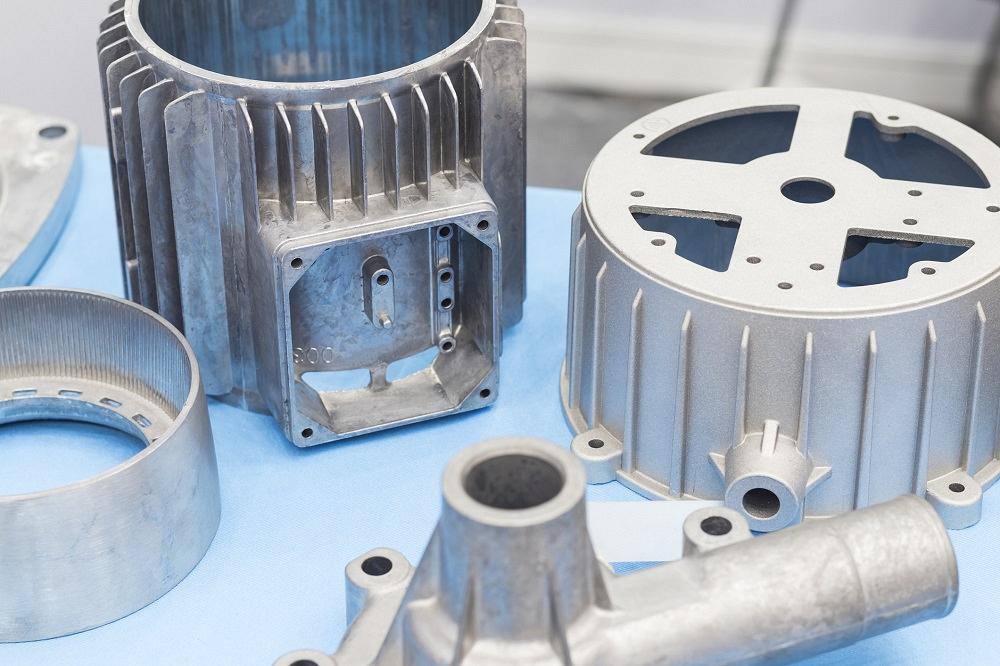

Aluminium Casting

Best Aluminium Casting:

Aluminium Casting is a versatile process used to shape molten aluminium into precise and functional components. Moreover, at CSG Extrusion LLC, we specialize in high-quality aluminium casting for various industries including automotive, aerospace, construction, and more.

Common Aluminum Casting Methods

1. Die Casting

2. Sand Casting

3. Investment Casting (Lost Wax)

4. Permanent Mold Casting

5. Centrifugal Casting

6. Gravity Die Casting

7. Vacuum Casting

Factors to Consider in Aluminum Casting

1. Part Complexity

Firstly, Investment or die casting handles complex, detailed shapes exceptionally well.

On the other hand, sand or gravity casting is more suitable for basic, straightforward designs.

2. Production Volume

When it comes to scale, for large production runs, die casting proves to be the most efficient method in aluminium casting.

Meanwhile, sand or investment casting offers flexibility for smaller batches.

3. Accuracy & Surface Finish

Best finish: Die and investment casting

General use: Sand casting

4. Size of Components

Large parts: Sand or permanent mold casting

Small precision parts: Die or investment casting

5. Mechanical Properties

High strength: Vacuum or centrifugal casting

Standard performance: Most casting methods

6. Budget

On a tight budget? Go for sand casting.

However, if you’re aiming for premium performance at scale, die casting is the way to go.

Applications of Aluminum Casting

Automotive: Engine blocks, gear housings (Die Casting).

Aerospace: Turbine blades, structural parts (Investment, Vacuum Casting).

Construction: Brackets, beams (Sand Casting).

Electronics: Housings, heat sinks (Die Casting).

Machinery: Suitable for high-load parts made with Centrifugal or Permanent Mold Casting.

Advanced Casting Techniques

Low-Pressure Die Casting

Controlled metal flow, minimal defects

Ideal for wheels and structural parts

Squeeze Casting

Combines casting & forging

Superior mechanical properties

Semi-Solid Casting

Reduced porosity, excellent finish

Aerospace & automotive use

Tilt Pour Casting

Minimizes turbulence and inclusions

Perfect for thin-walled component production