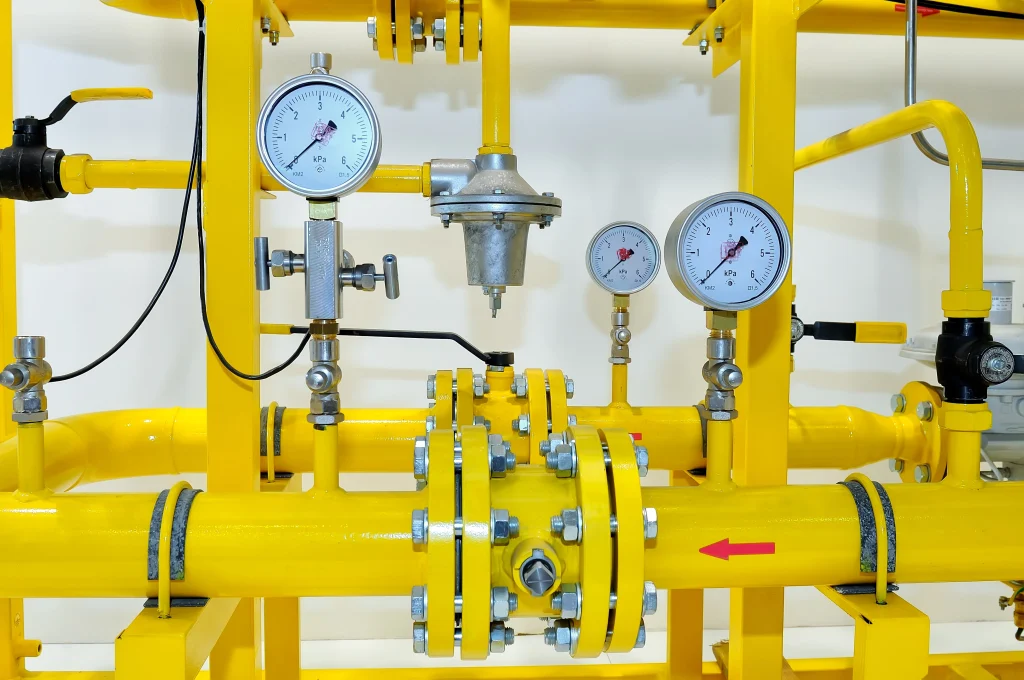

You look at a pipe. It seems solid. The welds are clean. The fittings hold tight. But can it truly handle the pressure when it matters? That’s not something you want to find out after it’s installed. That’s exactly why hydraulic pressure testing exists, not to impress, but to prevent failure. At CSG Extrusion, we emphasize hydraulic pressure testing awareness because it’s more than a routine check. It’s one of the last steps before we let anything out the door, and often, it’s the step that reveals everything.

It’s Not Complicated. But It’s Critical.

Hydraulic testing, in plain words, is a stress test. We fill the pipe or part with water, then push pressure through it, far more than it would normally face on the job. If it holds up, great. If not, that failure just prevented a serious breakdown later. Most people don’t think much about it, which is why hydraulic pressure testing awareness matters. That one test can be the difference between a smooth launch and an unexpected shutdown.

Why Bother? Because Real Life Doesn’t Forgive Weak Points.

Pipes crack. Valves burst. And joints leak. Especially in the UAE’s extreme industrial and marine environments. If something’s going to fail, it’ll do so when everything’s running hot and fast. That’s why hydraulic pressure testing is more than protocol, it’s protection. At CSG Extrusion, we see it all the time. Something that looked perfect on paper fails under pressure. It’s not anyone’s fault. Metal isn’t predictable unless you test it.

What We Test, And Where It Matters

Our clients come from all corners: marine firms, oilfield operators, infrastructure developers, and custom fabricators. Here’s the kind of equipment we usually put through the pressure test:

• Marine castings – especially ones dealing with seawater

• Pipelines and joints – including critical seals

• Alloy parts for heavy-duty machinery

• Custom-fabricated metal items made to spec

If it’s going into a high-pressure situation, underwater, underground, or in heat, we test it. Promoting hydraulic pressure testing awareness ensures our clients understand how vital this step is for safety and long-term reliability.

How We Approach It at CSG

We don’t just run the test and print a report. We look at the part like it’s going into our own system. We ask:

- Will it last five years or fifteen?

- Will it resist corrosion?

- Will it survive an unexpected pressure spike?

That level of care is what separates standard vendors from real technical partners. We use well-maintained equipment. We follow both UAE and international benchmarks. And we don’t rush the process just to deliver fast. If something fails, we tell you, no sugarcoating.

Many Don’t Take It Seriously Enough

Let’s be honest. Some companies skip pressure testing altogether. Others do it half-heartedly, short durations, low pressure, no proper observation. That’s not how it should be done. Hydraulic pressure testing awareness is about more than just ticking a box. It’s about making sure what you’ve built can take a hit without bringing everything else down with it.

One Final Thought

Hydraulic pressure testing isn’t glamorous. No one celebrates it. But it’s the quiet step that often saves projects, money, and even lives. Hydraulic pressure testing awareness reminds teams to never overlook this step. So before your next part gets bolted into place, ask the hard question: has it been tested right? At CSG Extrusion, we don’t just build strong, we test smart.