In the world of heavy industry, people often picture robotic arms and automated lines. But behind many of the UAE’s strongest, most reliable metal components is a tool that looks simple, but does something critical: the lathe. At CSG Extrusion, lath work UAE isn’t a backup; it’s a key part of how we meet the demands of marine, oil, gas, and construction clients across the Emirates.

Lathe Work A Quiet Powerhouse

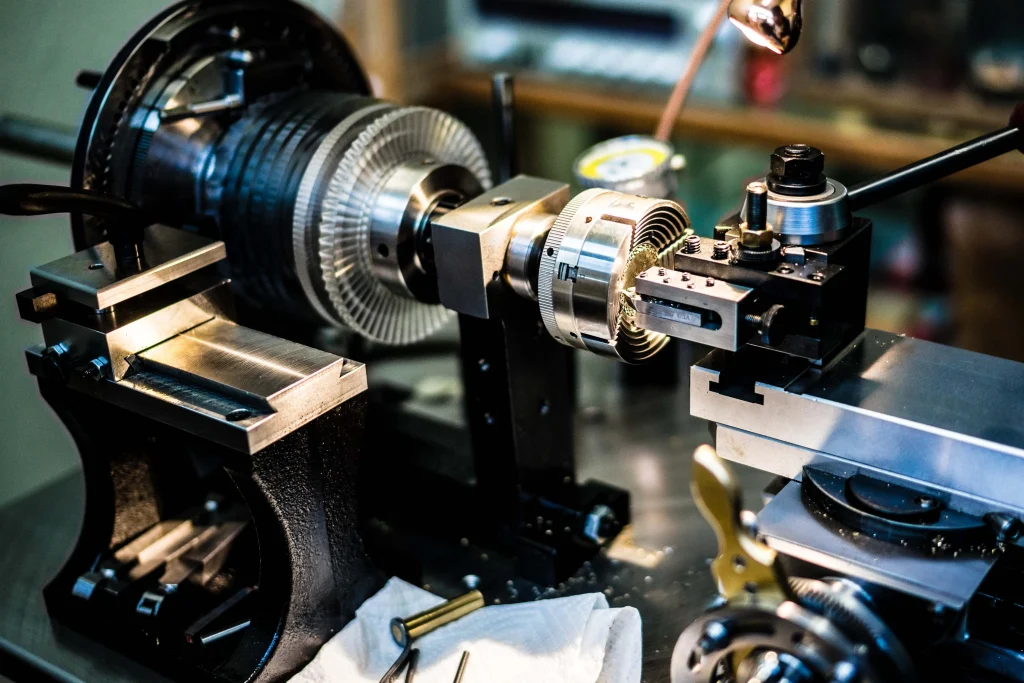

Here’s the thing: A lathe doesn’t flash or roar. It spins metal. A steady blade trims that spinning shape with care. But when the job calls for total precision, there’s no better tool. Our machinists don’t just operate the lathe, they perform lath work UAE. They listen to it. They feel when the metal resists or when it’s time to make a final touch. This experience turns raw castings into parts that actually fit, hold, and perform.

Why It Still Matters, Even Now

Technology has advanced. CNC machines are everywhere. But not every situation fits a program or a preset. That’s where skilled lathe work earns its place.

At CSG, we rely on our lathes when we need:

- Custom metal adjustments

- Single-unit or small-batch parts

- Smoothed surfaces for tight seals

- Threaded areas that won’t fail under pressure

We use a blend of manual and automated machines, choosing whichever gets the part done right.

From Casting to Completion: A Natural Flow

Everything starts with a casting, brass, iron, or aluminum. But casting only gets the part close. To work in a real-world system, it needs refining. That’s where our lathe team steps in to perform lath work UAE. They adjust size, smooth edges, align threads. Once the shaping’s done, the part heads to testing, usually pressure testing, where even minor imperfections show up fast. And because everything happens under one roof, from casting to machining to testing, we don’t waste time or compromise on quality.

What Sets Our Team Apart

Sure, machines follow instructions. But people notice what code can’t. Our machinists catch inconsistencies early during lath work UAE. A slight vibration, a tiny edge, a thread that looks “almost right”, they spot it before it causes a problem down the line. That’s what turns a decent part into one that lasts. We’ve saved clients rework and replacements just by making one extra pass or correcting a thread depth by half a millimeter.

Serving Dubai and the UAE’s Backbone Industries

The metal parts we machine don’t sit on shelves. They go straight into:

- Ship engines and marine shafts

- High-pressure pipe systems

- Large-scale HVAC assemblies

- Construction and infrastructure works

From Dubai to Abu Dhabi, we support firms who can’t afford downtime. They count on CSG’s lath work UAE to help keep their operations running smoothly.

Final Thoughts: The Last Cut Matters Most

You can’t always tell from the outside which part was finished on a lathe. But you’ll know it when the system runs without leaks, breakdowns, or failures. That’s the difference skilled lath work UAE makes. And that’s what we focus on at CSG Extrusion, doing the work that others overlook, but that makes all the difference.