Hydraulic Pressure Testing

What is Hydraulic Pressure Testing?

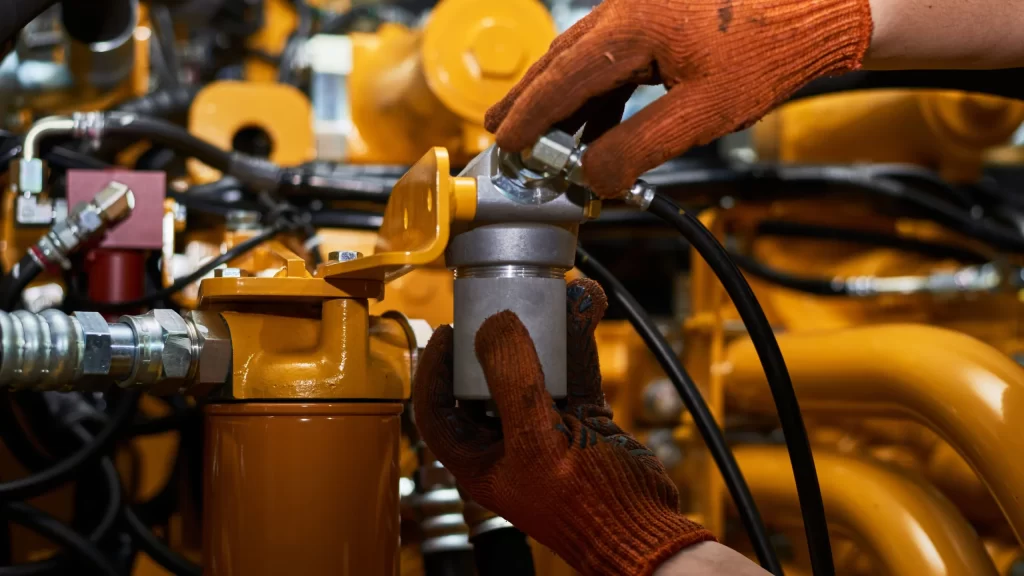

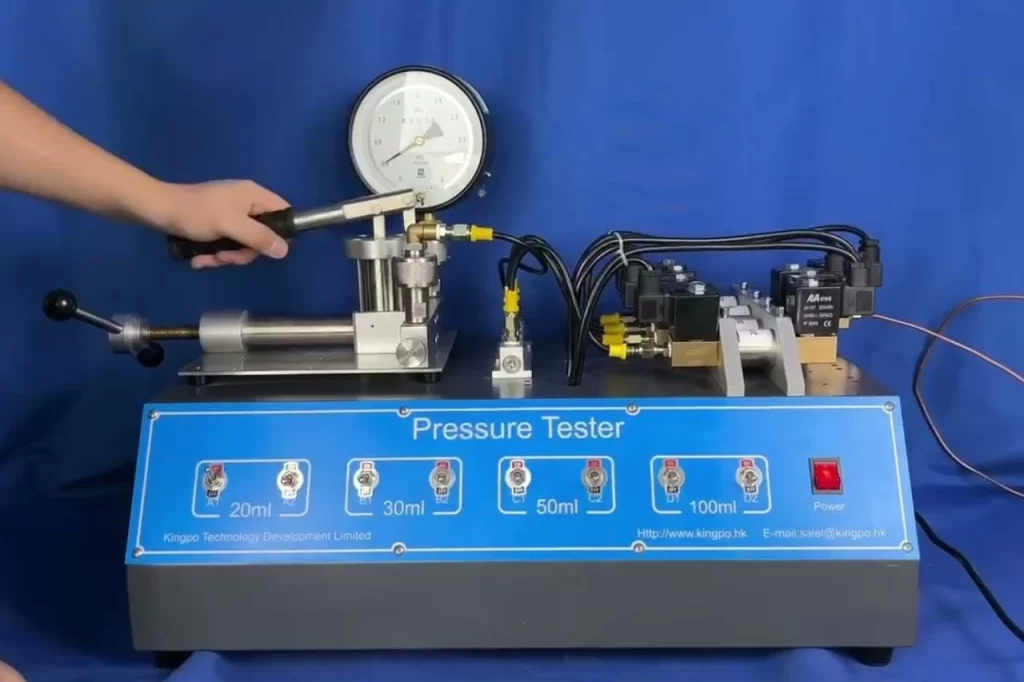

Hydraulic pressure testing is a safe and non-destructive technique used to verify the durability and leak resistance of pipes, tanks, valves, pumps, and cast components. The process involves pressurizing the system with fluid (usually water or oil) at a predetermined level and monitoring its response to detect any weakness or failure points.

Moreover, at CSG Extrusion LLC, we follow strict industry standards and safety protocols to perform accurate and efficient tests for our clients in the UAE and beyond.

Why it is Important?

Hydraulic pressure testing is critical for:

Ensuring components can withstand high-pressure conditions.

Additionally, we uncover hidden leaks or structural flaws well before your equipment is set up or brought online.

This helps in preventing potential system failures or hazards.

Meeting industry certifications and regulatory compliance.

Whether it’s a newly cast part or a refurbished pipeline, testing it under pressure ensures its readiness for real-world performance.

Our Hydraulic Testing Capabilities

We conduct precision testing on a diverse range of components, including:

Cast iron and aluminum parts

Flanges, pipes, and valves

Marine and industrial equipment

Hydraulic cylinders and tanks

Customized castings

Our advanced pressure testing equipment enables us to perform both low-pressure and high-pressure tests with accurate results and detailed reporting.

Industries We Serve

CSG Extrusion LLC provides hydraulic pressure testing services to various industries, such as:

Marine and shipbuilding

Oil & gas

Construction

HVAC and plumbing

Manufacturing and heavy machinery

Furthermore, our flexible testing methods can be tailored to your specific industry needs and quality requirements.

Why Choose Us?

Experienced team of engineers and technicians

State-of-the-art testing equipment

Fast turnaround with precise results

Comprehensive reports for documentation and compliance

Strict safety and quality control protocols